We look around and get a deep understanding of what is happening in industries and then we think about it differently. Our unique analysis and insight help us to find the interconnections that will provide long term opportunities.

We take these insight and deep knowledge about our wide-ranging interconnected customers and vendors letting them communicate to us what pain points and opportunities for improvement are. We hear what they what and will buy.

We use our customers' focused data to innovate and create a solution to solve their issues. Every development needs to have a significant differentiated competitive advantage over the long term and the ability to produce a new scalable product or company.

We then input the solution into our nimble, decentralized entrepreneurial market silos that uses an 80/20 front to back and customer focused process to sell and manufacture products and services that create high quality organic growth while still being capital efficient.

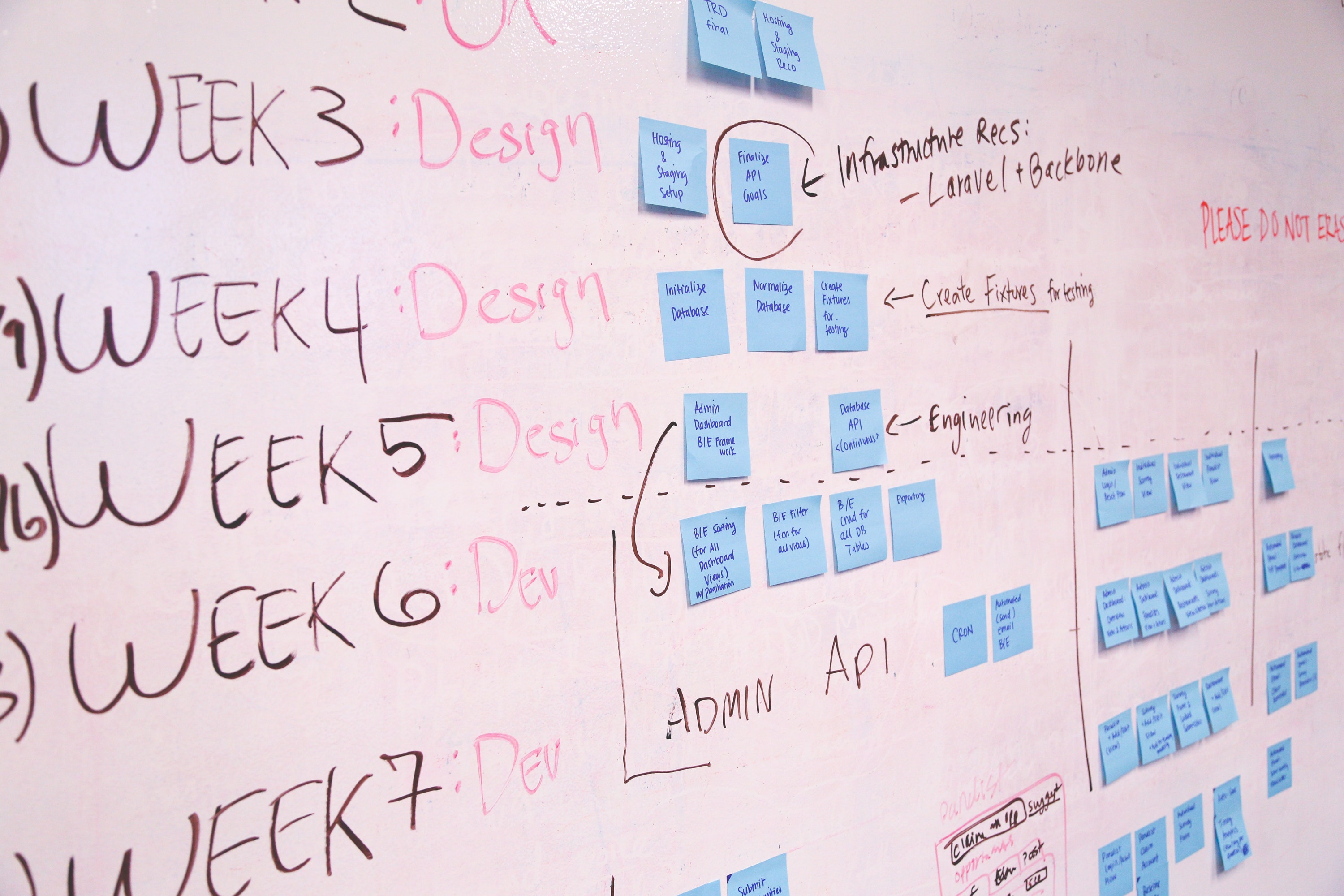

Developing ideas that are supported by positive long-term macro fundamentals and trends, we use a set of strategies, operational and cultural practices that uses knowledge-based and customer focused innovation to create a product or solution.

We then introduce the solution into one of our Market Silos where we drive operational excellence with a continuous feedback loop to deliver best in class product and service that can deliver solid growth and long-term value for all the stakeholders.

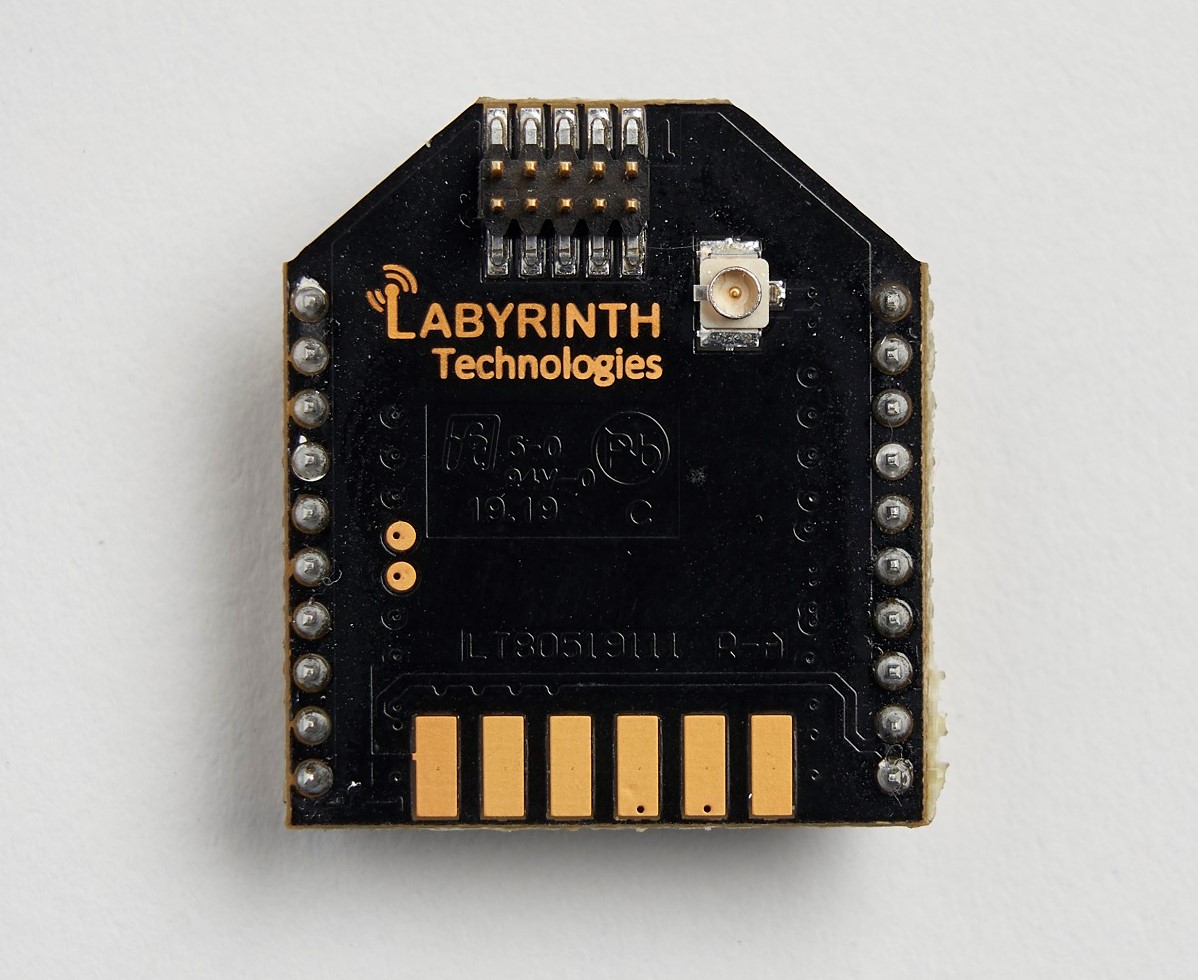

Our talented team of professionals representing diverse skill-sets fuels our capacity to solve our customers problems by engineering innovative technology.We support creative problem-solving with our experienced electrical, mechanical, and software engineering teams. In-house designing, prototyping, and manufacturing turn a concept into a product.

We have in-house mechanical, electrical, and structural engineering capabilites. Having all these expertises internally allow us to rapidly innovate to keep up with any requirements or design challenges.

We program every part of our systems. From embedded assembly code, networking code, microservices, web interfaces, and database design. Having full stack capabilites lets us develop complex products easily.

All our circuits are designed in house for maximum software-hardware integration capabilities.

Utilizing numerous prototyping technologies including 3D printing, laser cutting, breadboard circuit design and others, we can develop proof of concept products quickly before shifting ready products into our manufacturing capabilities.

In house capabilites for laser cutting, robotic material preparation, welding, machining, injection molding, wire harness preparation, software loading, and final assembly.

We have trained personnel for deploying devices in the field on city infrastructure. With years of experience, they can adapt to the numerous on site issues that can occur with smart city deployments.